If we think about it, the handlebars are the only part of the bicycle that we can hold on to and without handlebars it is practically impossible to steer the bicycle.

The handlebar actually consists of two parts: the handlebar bend and the stem. We are of course talking about vintage racing bikes, with some modern handlebars the handlebar bend and stem consist of only 1 block.

With these two parts we can look for an ideal position (provided the frame is not too big or too small). With the length of the stem we can sit more forward or back, we can raise or lower the handlebars. The width of the handlebar bend can also vary.

The handlebar bend

The handlebar bend is colloquially referred to as handlebars and was made of steel in the early days of the bicycle's creation. Only around the middle of the last century was the much lighter aluminum used and nowadays all road bikes from a certain price range are equipped with a carbon handlebar.

In cycling there are (were) different types: the classic round handlebar, the triathlon handlebar and the bullhorn handlebar (replaced by the triathlon handlebar).

A special handlebar that was launched in the 1990s, but was banned by the UCI after a few years because it was too dangerous, is the Cinelli aerobar that allows you to turn your regular handlebar into a triathlon handlebar. This handlebar was known as the spinacci.

The handlebars used on the first racing bicycles looked slightly different from those used from the 1930s. They were made of steel, narrower but with a greater curvature and not equipped with a handlebar tape but only with 2 handles at the end.

The gradual transition from steel to duralumin only happened gradually because aluminum has the disadvantage that it is less strong and many riders are rather suspicious of it, but since the 1970s this suspicion has completely disappeared.

In that period there is even an Italian and a Belgian handlebar bend. The Belgian is rounder in shape while the Italian is more rectangular and has a longer straight piece at the top.

The handlebar bend is slid into the stem and secured in the middle. A not so easy job where you have to be very careful not to scratch the handlebars. The brake levers or shifters are attached to the handlebars.

The width of the classic round model varies from 37 to 42cm, although the first handlebar bends were very narrow. Only later did they become wider because ever better aluminum alloys were used and generally the rule applies that the wider the more the lungs are open and the more air can be inhaled and a wider handlebar bend therefore also has more stability.

The stem

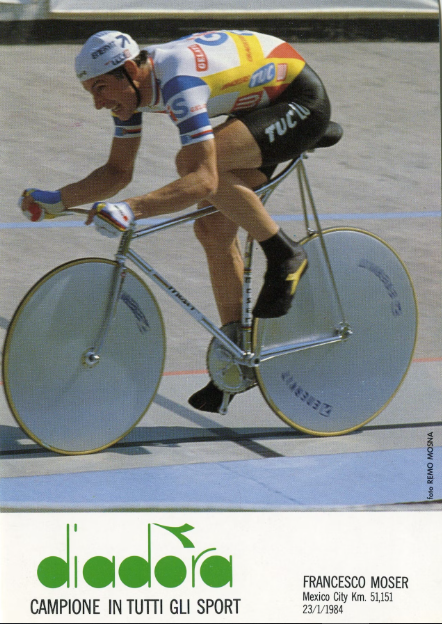

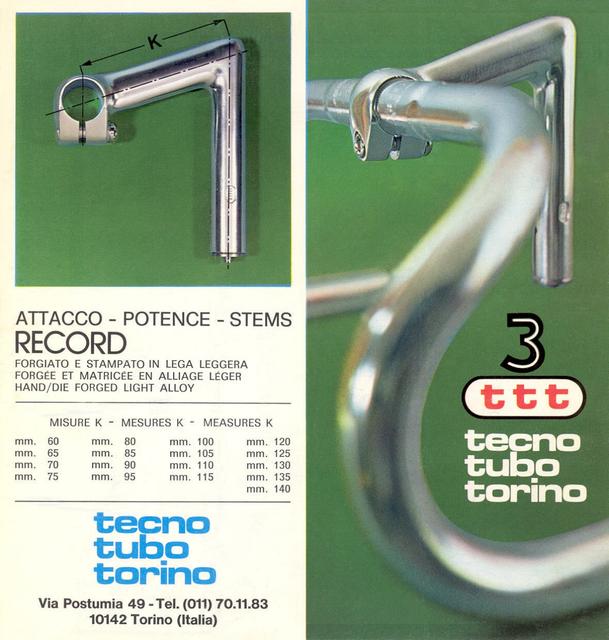

The stem is the part of the handlebar that secures the handlebar bend to the frame. Compared to the handlebar bend, you have even more variations here, ranging from 60 to 140mm. Sprinters liked a long stem.

At the bottom of the stem you can see the expander with which it is secured in the head tube. In the beginning, bolts still protruded from the stem, but Cinelli released a model in which the bolts (Allen bolt) were integrated into the stem. These are then covered with a plastic plate that usually bears the logo or name of the brand.

As a result, the handlebars had become completely smooth and there were no sharp edges protruding that could cause physical damage in the event of a crash.

If you want to remove a handlebar from the head tube, you first have to loosen the bolts, but then you have to give a big knock (with a rubber hammer) on the head of the stem so that the expander comes loose. If you don't do this, you won't get the steering wheel out, no matter how hard you try.

The stem was also used by artisan bicycle makers to engrave their brand. They are still sought after by collectors.

The main manufacturers of handlebar bends and stems were:

- From Italy: 3ttt (Tecno Tubo Torino), Cinelli, Italmanubri (ITM), Ambrosio

- From Japan: Sakae Ringyo (SR)

- From France: Atax, Belleri, Mavic, Milremo, Philippe

Handlebar tape

Because a handlebar bend is bare and smooth, it is finished with a bar tape after the brake levers or shifters have been fitted. Here too, throughout the history of cycling, many different materials and designs have been introduced to the market: cotton, plastic, cork, leather.

A special type of bar tape that is still popular with collectors of vintage racing bikes is the Benotto bar tape from the Italian manufacturer Benotto. This type of handlebar tape is made from a vegetable material from Mexico. It has the advantage that it is washable but not slippery, which is an advantage over the other types of plastic.

The handlebar tape that was on the racing bikes of the French Motobecane can also be called quite special. It was made in 1 piece which also contained the brake levers. The handlebar tape was placed on the handlebar and then sewn (by hand or by machine is still not clear to me, so all info is welcome). The handlebar tape was patented by Motobecane in collaboration with Hutchinson.

The handlebar tape at the bottom is attached to the handlebar bend with the help of bar ends. These ensure that the apple corer effect does not occur during a fall, whereby the open end of the handlebar bend penetrates somewhere in a body part.