In the article How is a steel frame build we already talked about the lugs, or the elements that connect the main tubes of a frame. In this article, we'll take a closer look at that.

In general we can say that there are 3 types of lugs:

- upper headset lug

- lower headset lug

- seatlug

The lug in which the bottom bracket is located is called the bottom bracket, and the connecting pieces between the upright and chainstays are called the pads or dropout. The two legs of the front fork are then again held together by the fork crown.

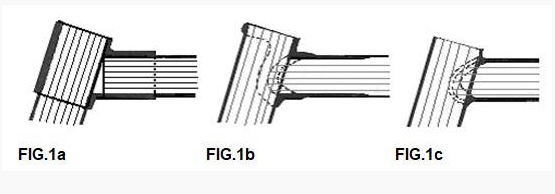

External and internal lugs

The lugs can be either external or internal. With the external lugs (also called tube in lug), which is most often used with steel frames, these are visible and the tubes are partly located in the lugs. It often happened that the framemakers would engrave their logo or name on the lugs and bottom of the bottom bracket.

This was not only a good advertisement but was also to mark their frames.

With the internal lugs (also called lug in tube) or lugless frames, you can't see the lugs and they are located internally in the tubes.

Production lugs

The first lugs were cast. This process was already used in the 19th century and is similar to that of cast iron in which the lugs are poured into a mold filled with sand or resin.

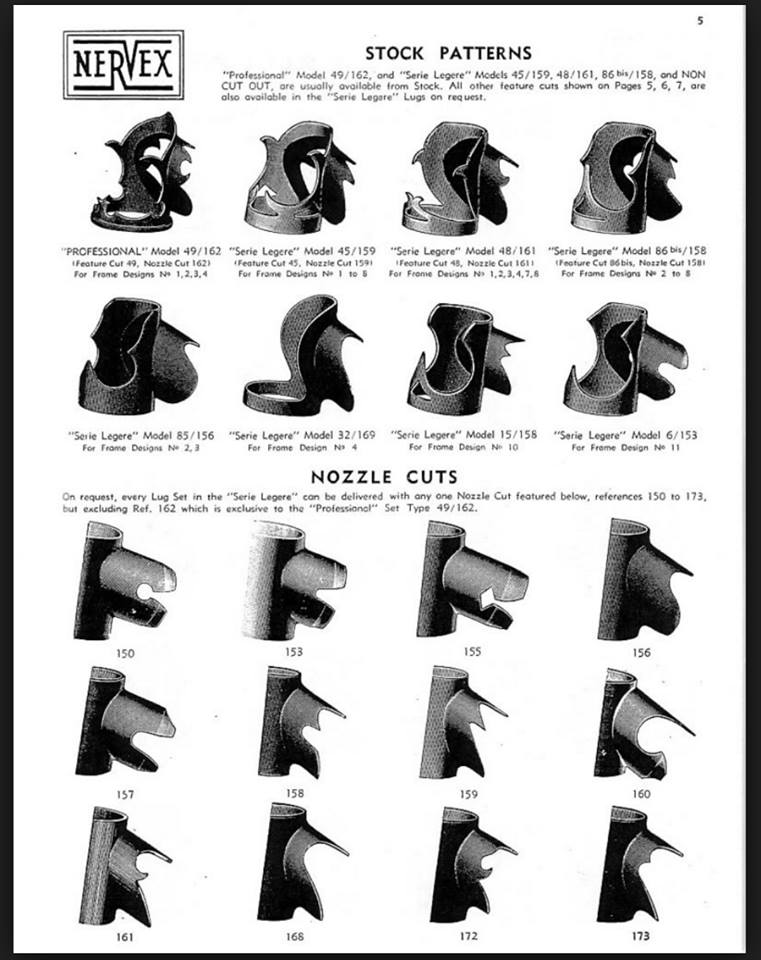

However, the most commonly used manufacturing method is by pressing steel plates around a mold and then welding. The finish of these so-called rough lugs (blancs) depends on the quality and purpose of the bike. The degree of finish differs quite a bit for a simple bike from a professional racing bike.

On a simple bike, the lugs are cut straight and thicker and the tubes fit in easily. With a professional racing bike, the lugs (and the tubes) should be as light as possible and the lugs are therefore trimmed until only the most necessary material remains. The result is that you get nicely cut lugs. Some manufacturers of lugs turned them into real gems. An example are the Nervex lugs.

Another advantage of these cut-out lugs is that the surface area for the connection to the tubes is larger and so there is more surface area to weld or braze. It goes without saying that the fit (the fitting of the tubes in the lugs) must be done perfectly and this is therefore more difficult to perform with the thinner, narrower lugs.

The most commonly used lugs, at least in the Netherlands, were Prugnat, Bocama (BCM) and Vagner. The bottom brackets came from RGF (Raccord Gargatte Frères) and Cinelli.

braze

With steel frames, the tubes and lugs are connected to each other by means of hard soldering, also called brazing. For soldering, a silver, copper or brass alloy is used. When you remove the paint from a steel frame, you can still see the yellow color of this alloy on the connecting pieces.

The first aluminium lugs

At the end of the 1970s, the Italian Alan and the French Vitus came onto the market with aluminum tubes and lugs. These tubes had threads with which they were fixed in the lugs and then glued. A completely new way of mounting a frame. Aluminum tubes were also a lot lighter than the steel tubes, which was a serious advantage.

The disadvantage of these lighter aluminum lugs was that they were more brittle and therefore more fragile. It happened more often that small cracks occurred.

Later still, the lugs in aluminum remained, but the tubes were replaced by carbon tubes. The first bicycle manufacturer to make professional use of this was the French Look. In the 1986 Tour de France, Greg Lemond and Bernard Hinault were the first to use a frame with carbon Kevlar tubes.

With the rise of TIG welding and later carbon bicycles, the use of classic steel and aluminum lugs gradually disappeared from the 1990s. Fortunately, with 3D printing there is a small revival where the lugs are printed.

In the video below you can see how a steel frame is attached to the lugs by means of brazing.